|

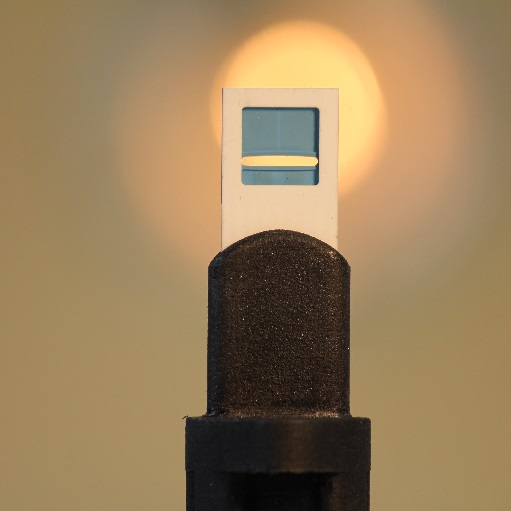

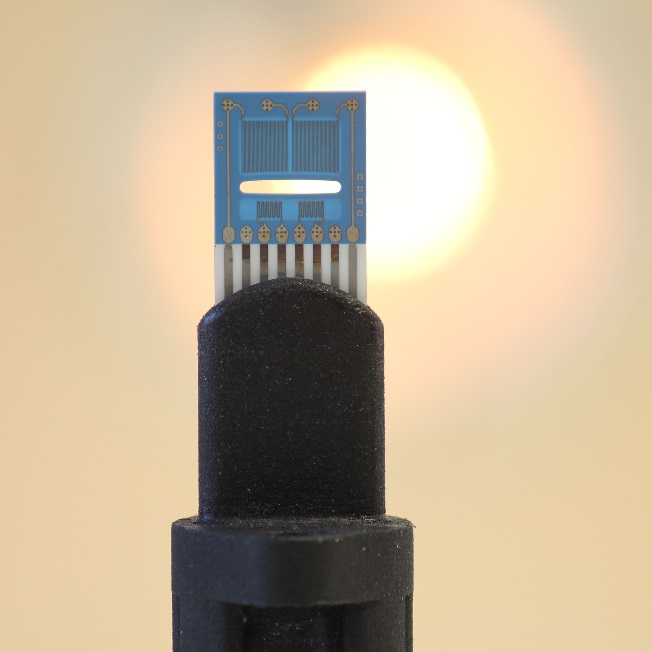

The project goal is to develop a pulsatile mass flow sensor, which allows both a determination of the exhaust gas mass flow of combustion engines, and is suitable for use in portable emission monitoring systems. The aim is to select a material-hybrid approach from miniaturized, highly robust, ceramic sensor elements and thermally decoupled housing as well as an adapted, high-temperature construction and connection technology. For control, measurement and signal processing, a control and evaluation electronics is developed which ensures the use in harsh environmental conditions. On the basis of the developed sensor, the next step will be to develop an EGR system that will be integrated into suitable engine test benches and evaluate its influence on fuel consumption and emissions. The work plan consists of a total of 10 segments. These are described separately in the Sub-project description and are referred to as WP = work package.

|