|

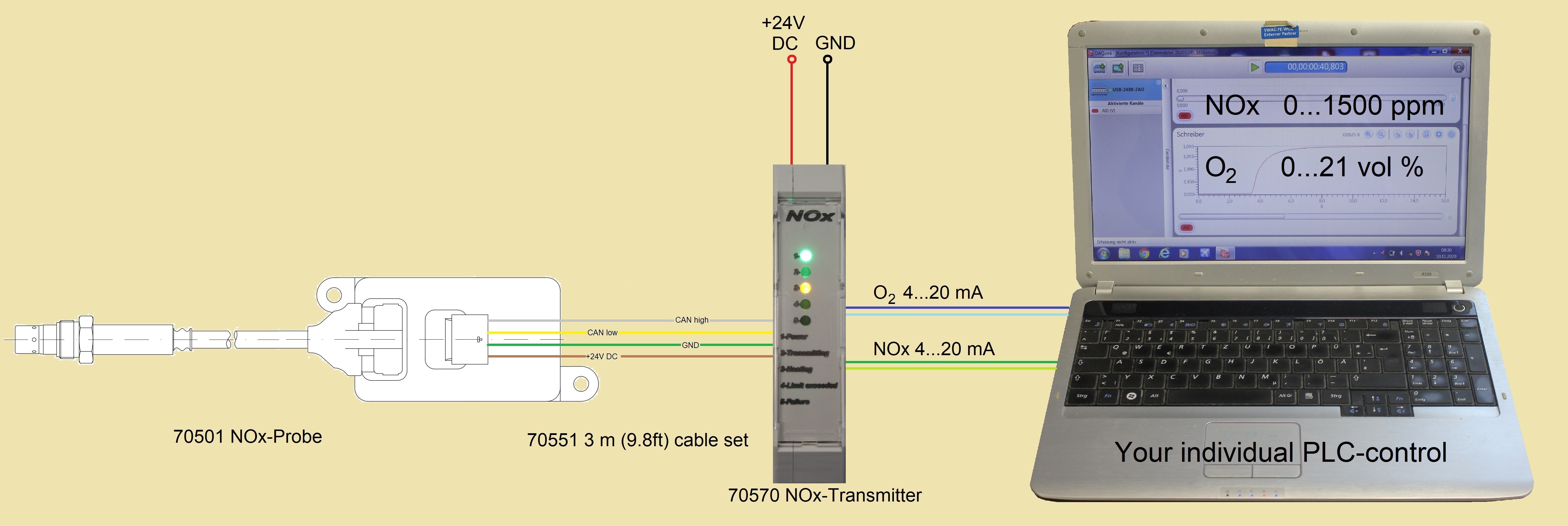

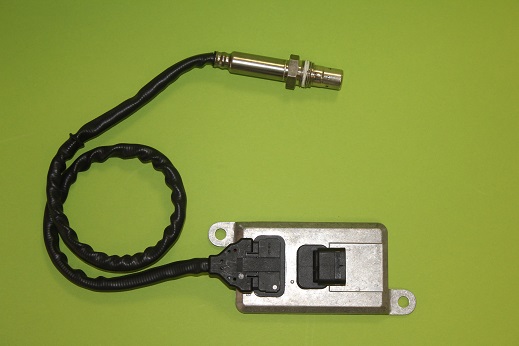

The transmitter converts the CAN bus signal from the nitrogen oxide probe into 4-20 mA. The NOx probe also outputs the oxygen content under lean exhaust gas conditions. Both values are transmitted in 4..20 mA according to a conversion table. The nitrogen oxide concentration is measured in ppm and the oxygen concentration in vol.%. Both values are given in mA. Nitrogen oxide sensors are generally are sensitive against water vapor and condensate. The risk of water hammer is greatest immediately after starting the engine. The ceramic sensor tip is heated to 800 ° C during measuring operation. If this is hit by a drop of water, it shatters immediately. For this reason, the probe preheats to 80 ° C after switching on the tip. The transmitter requests five minutes until the engine runs normally, i.e. emits little water vapor, and then sends the dew point end signal to the probe. This then heats up in stages up to the operating temperature and begins measuring the nitrogen oxide content in the exhaust gas, which will now become mA values. The transmitter is intended for top hat rail mounting and shows the operating status via status LED.

|