|

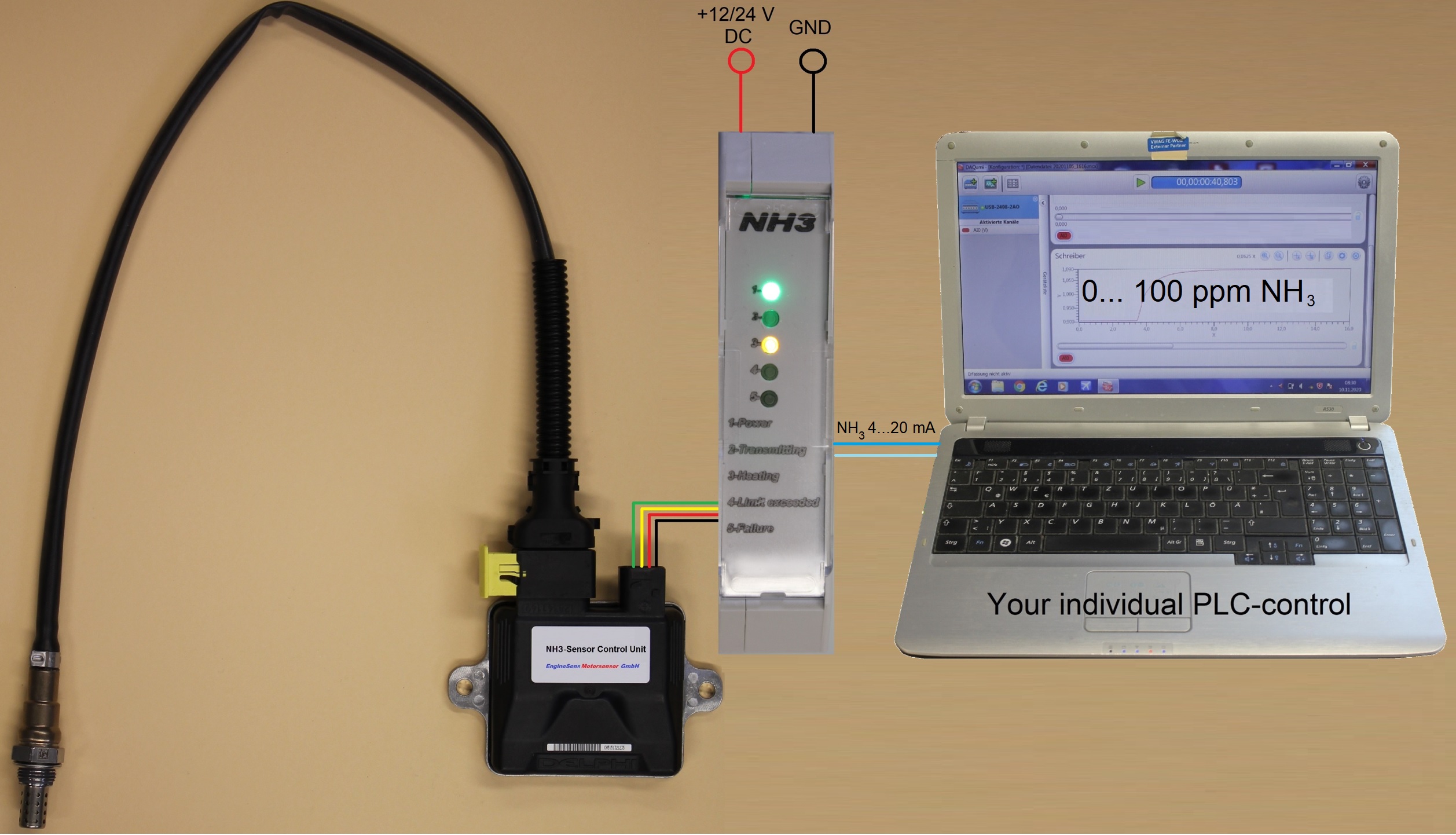

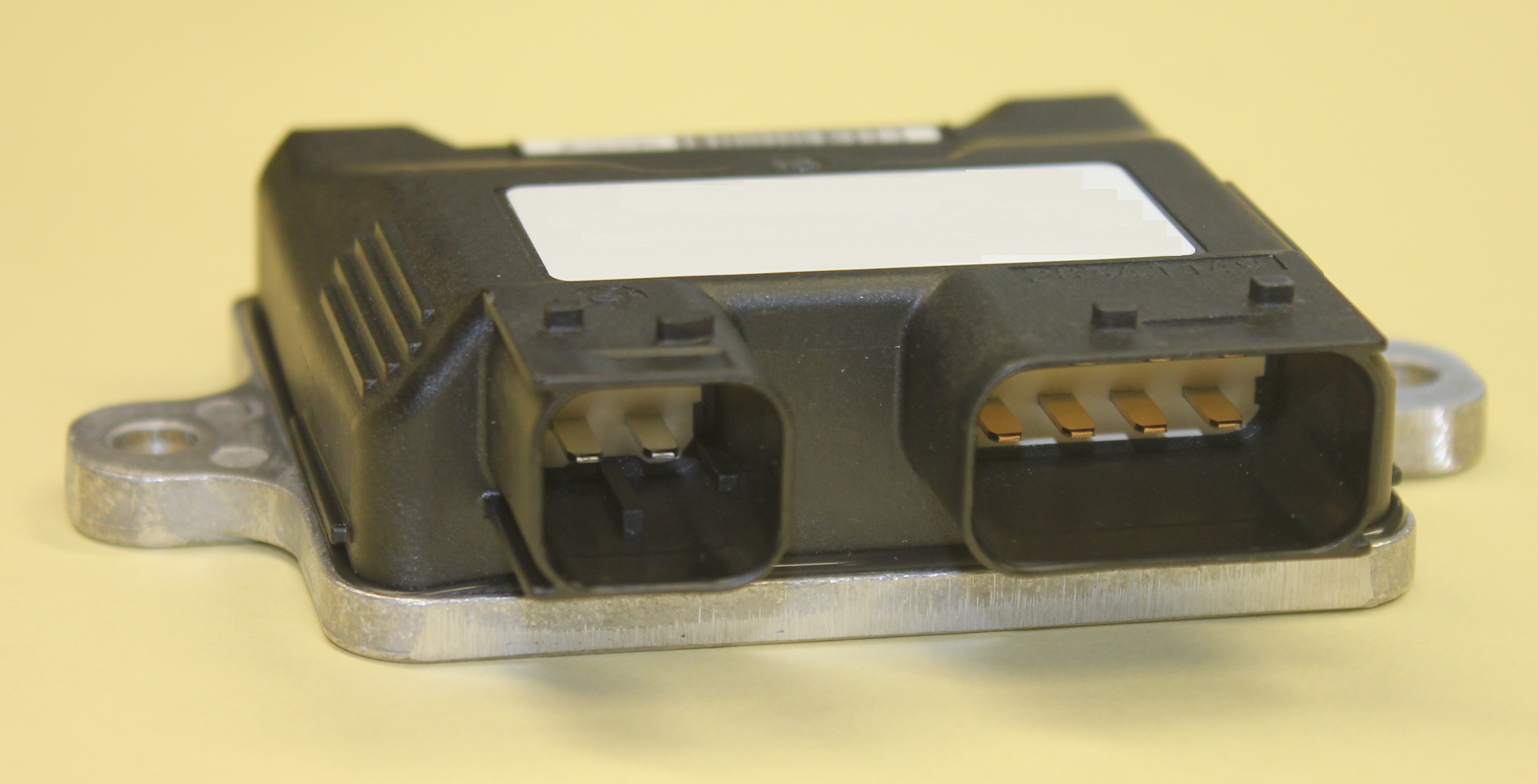

Based on a series-manufactured ammonia sensor, EngineSens Motorsensor GmbH developed an NH3 monitoring system consisting of the sensor, a sensor control unit, the wiring harness and a transmitter. The NH3 sensor, proven in commercial vehicles, is a heated gas sensor with an Al2O3 substrate. A separate sensor control unit (SCU) controls the heating element. The ammonia content is transferred to the transmitter as a CAN bus message via a cable with a maximum length of 15 m (50 ft). This outputs the ammonia content as an analog signal 4...20 mA, which can be processed by any PLC control. This significantly simplifies the monitoring of SCR catalytic converters. These generally use a nitrogen oxide sensor with zirconium oxide ceramics and are cross-sensitive to ammonia in the 0…300 ppm range. It is impossible to differentiate between ammonia and nitrogen oxide at these concentrations. The user must find out by testing whether there is an overdose or underdose of DEF. With the "NH3 monitor" there is no doubt. A more precise dosing strategy is possible. The ammonia sensor is designed to last more than 5,000 hours and can be easily replaced. First pilot plants in Austria and California have successfully started operation. Target applications are exhaust gas cleaning using SCR from biogas plants, combined heat and power plants (CHP), GenSets, off-road and

|